Allmatic

Artikelnr: 6921538000055

Description:

Product features:

- Standard with mounting holes for zero point clamping system, Pitch 200

- The centre is adjustable. The position of the workpiece stays within set boundaries

- Repeating accuracy ± 0,01 mm for rectangular workpieces

- Guides ground, polished and paired

- Clamping range presetting via adjustment of clamping jaws along transverse slots of spindle nuts

- Moulding and clamping in a single step, directly in the work area – no auxiliary aids required

- Use with a torque wrench – max. 70 Nm

- Fully enclosed and maintenance-free high-pressure spindle – high chip protection, minimum cleaning requirements, constant clamping forces up to 40 kN

- Fixing via the hole grid on both sides or alternative with side clamps

- Horizontal installation – suitable for vertical CNC-controlled milling machines

- Ideal for use on 5-axis machining centres due to its compact design

- Depending on the clamping jaws, both pre-machined workpieces and unmachined parts can be clamped

- With support jaws, unmachined parts with varying types of flame cut and sawn materials and even complex castings can be clamped safely and economically. Gripp-studs suitable for materials of mechanical strength of up to approx. 1000 N/mm²

Scope of Supply:

- 1x high-pressure vice without jaws

- 2x combination wrenches

- 6x fastening screws, M12 x 35 mm

- 2x socket screw wrenches

- 1x wrench socket

- (Please order clamping jaws separately)

-

Specifikation

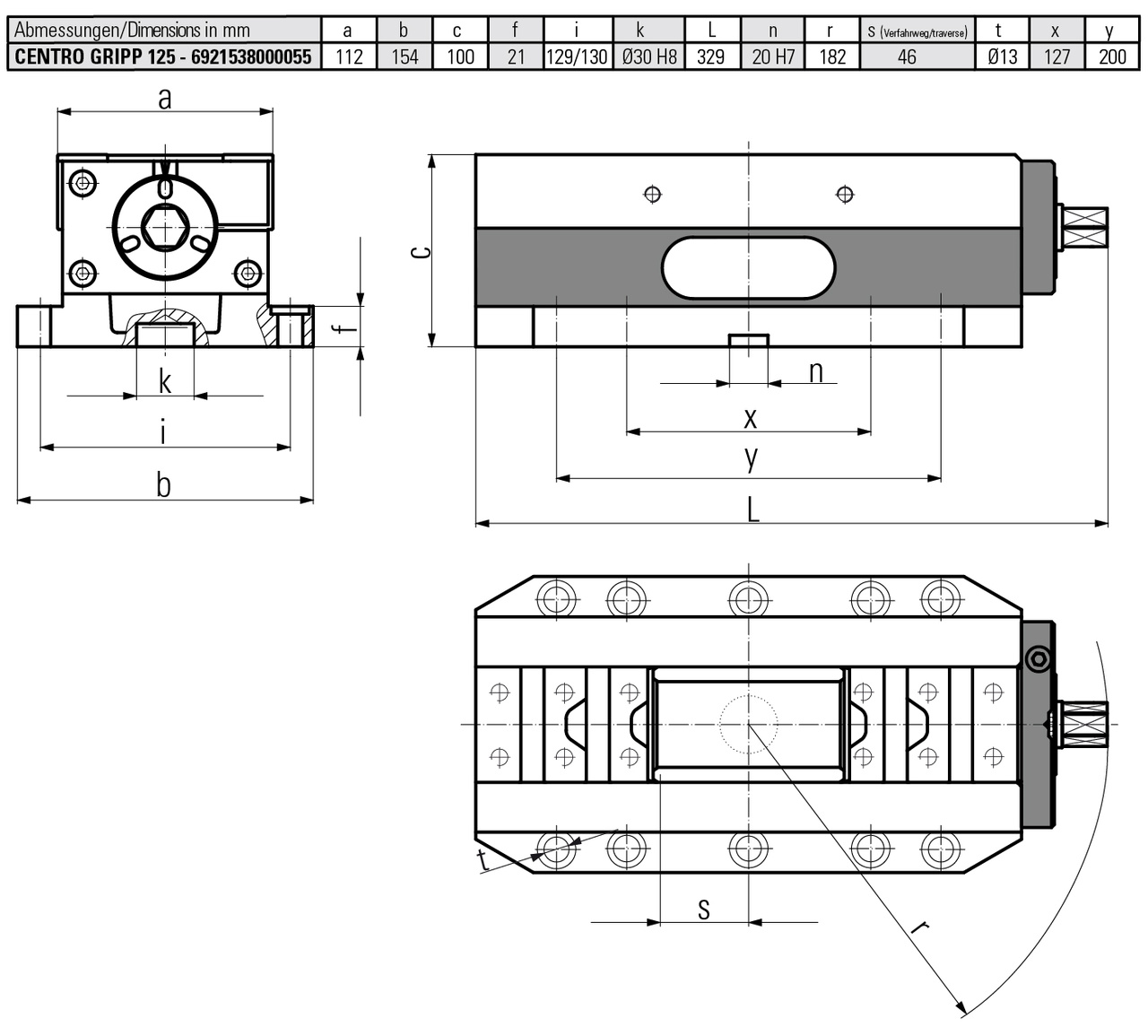

Max. torque (Nm) 70 Max. clamping force (kN) 40 Version Mechanical Workpiece Raw parts, Pre-machined parts Jaw width (mm) 125 max. Clamping range (mm) 256 min. Clamping range (mm) 0 Dimensions/mm - a 112 Dimensions/mm - b 154 Dimensions/mm - c 100 Dimensions/mm - f 21 Dimensions/mm - i 129/130 Dimensions/mm - k Ø30 H8 Dimensions/mm - n 20 H7 Dimensions/mm - r 182 Dimensions/mm - s 46 Dimensions/mm - t Ø13 Dimensions/mm - x 127 Dimensions/mm - y 200 Dimensions/mm - L 329 -

Teknisk information

Teknisk information